Collection: Stay Dry and Pul Wholesale Fabric

Nature's fabrics 1 mil PUL fabric (polyurethane laminate) is free from metals, phthalates and latex. It is produced in accordance with new PUL application standards (TPU). There are no VOC's (volatile organic compounds)emitted during production. Perfluorooctanoic acid (PFOA) and perfluoro octane sulfonate (PFOS) free. Phthalate free and lead free. Latex and BPA free. PVCs, diisocyanatos, chlorine, or migratable plasticizers free.

A hot melt adhesive system (TPU) is used to bond the fabric to the film. This system is also considered a "green" way of lamination! It has been tested and is holding up well in all applications that call for a 1 mil moisture barrier. Terrific for diaper covers, bibs, raincoats and mama pads. 60" wide. This is the new industry standard for pul. All made here in the USA! Meets all CPSC (consumer product safety commission) requirements for lead, phthalates and flammability.

All of the PUL (TPU) we offer at Nature's Fabrics is free from BPA, lead and 10 different phthalates. It is also free of ALL fluorinated chemicals PFAS , PFOA and PFOS. The PUL is FDA accepted.

FDA Regulation of Food Contact Materials

There is the potential for transfer of chemicals from the packaging to the food, which is why FDA regulations surrounding food contact materials exist. Understanding this legislation is key to coffering safe and legally compliant snack bags.

In the US, the regulatory status of a food contact material or article is determined by the regulatory status of each individual substances that constitute the material or article. A substance intended for use as a component of materials used in manufacturing, packaging, transporting, or holding food (also known as food contact substance) is regulated as indirect food additive under the Food Drug and Cosmetic Act (FD&C Act) and Title 21 Code of Federal Regulations (21 CFR). A food contact material or article is compliant only if all food contact substances contained have got FDA clearances.

It should be noted that only those food contact substances that migrate to the food (i.e., expected to become a component of the food) are regarded as indirect food additives and require FDA pre-market clearance. For example, if a substance is separated from food by a functional barrier and prevented from migration, the substance will not be considered as indirect food additives, and thus not require FDA clearance.

-

White Suedecloth Fabric - $6.78 per yard - Rolls

Regular price $488.16 USDRegular priceUnit price / per -

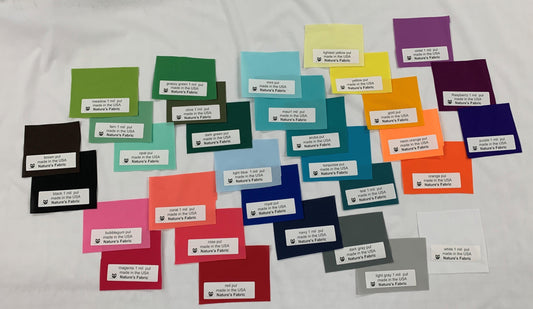

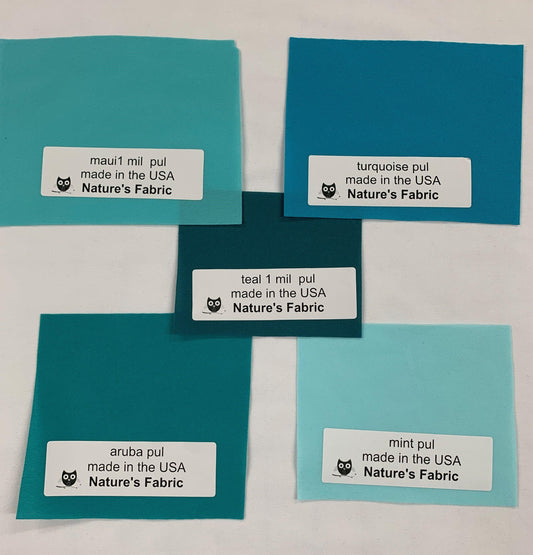

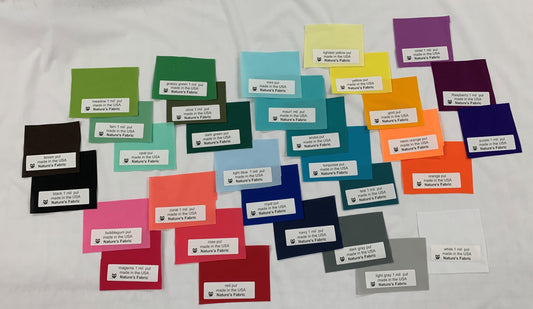

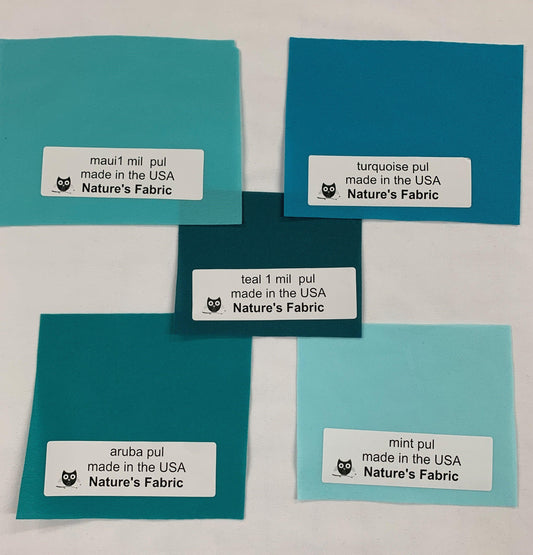

Polyester 1 MIL PUL Fabric, $5.99/yd, 50 Yards - Your Choice of One Color

Regular price $349.50 USDRegular priceUnit price / per -

Custom Print on 1 mil PUL Fabric- Made in the USA

Regular price $1,250.00 USDRegular priceUnit price / per -

Custom Print on 1 mil PUL Fabric- Made in the USA-Strike

Regular price $15.00 USDRegular priceUnit price / per -

Polyester 1 MIL PUL Fabric, $15.25/yd, 15 Yards - Your Choice of One Print

Regular price $228.75 USDRegular priceUnit price / per -

Polyester 1 MIL PUL Fabric, $7.65/yd, 15 Yards - Your Choice of One Color

Regular price $129.75 USDRegular priceUnit price / per -

2 mil White Polyester PUL Fabric, $4.99/yd, 100 Yards

Regular price $499.00 USDRegular priceUnit price / per -

2 mil White PUL Fabric, $5.99/yd, 15 Yards

Regular price $89.85 USDRegular priceUnit price / per